welding grinding services

Weld Grinding 3M Abrasives

Weld grinding is an important step in many metal fabrication processes, and cleanly removing the excess weld metal requires an abrasive that can be used both quickly and

WeldingGrinding Hi5 Metal Fab

WeldingGrinding. Hi5's team has 30+ years of experience in metal fabrication, providing a guarantee that parts are made correctly utilizing the most efficient processes. GMAW.

Tube Welding, GrindingPolishing GJ

At G&J SteelTubing, we have more than 40 years of experience with the above welding methods. We can help you fabricate steel or other metal

Micro WeldingCNC Machining Pomona, CA B&D

Micro Welding, MachiningGrinding Services. BD Precision has been creating long lasting relationships with our customers since 1983 by providing quality work with quick

Grinding Down Welds: How To and Should You?

While grinding your welds, you end up removing some of the thickness from the weld and the base metal. Grinding welds does inherently does lead to a reduction in the strength of

Welding and Grinding ? Royal Welding

2023年1月14日 Welding and Grinding ? Royal WeldingFabricating. Skip to content. 714-680-6669 714-680-6646 1000 E. Elm Ave. • Fullerton, CA 92831 info@royalwelding. Home. Tanks. Vacuum Chambers.

Robotic GrindingAutomated Material

Robotic Offroad Bumper Grinding. As an illustration, this video shows how effortless robotic grinding can be. In fact, a robot paired with a PushCorp force compliance device and servo spindle is just what you need to

Cylindrical Grinding CNC Machining HTS Coatings

MachiningGrinding. In addition to thermal spray, HTS Coatings is a full-service precision machine shop. We offer both machining and grinding and can perform precision lathe

Grinding Goldschmidt

Using manual and semi-automatic grinding, reprofiling and deburring machines as well as road-rail grinding vehicles, Goldschmidt maintains the quality of your railway tracks

Bandsaw Welding Service Sun Rise Technologies

High-End Bandsaw Welding Machine. We use specialty high-end band saw welding machine designed, built, and imported from Italy. We can weld your bandsaw accurately

Quantitative grinding depth model for robotic weld seam

2023年3月3日 The service cycle and dynamic performance of structure parts are affected by the weld grinding accuracy and surface consistency. A flexible abrasive belt wheel used to grind a weld can avoid burns on the base material and improve the grinding efficiency. the weld grinding experiment system includes an industrial robot (KR210R2700),

Manufacturing — Metal CraftRiverside

Grinding Fine finishes and precise dimensions perfect your product. And our CNC 7-axis grinding machines can custom form rasps, drills, taps, and reamers out of almost any material to your exact specifications. Welding Welding services are a very specialized area, which is why we offer both GTAW and laser-beam Welding. We’ll recommend the

Micro WeldingCNC Machining Pomona, CA B&D

Micro Welding, MachiningGrinding Services. BD Precision has been creating long lasting relationships with our customers since 1983 by providing quality work with quick turnaround times and reasonable prices. Whether you need a minor cosmetic repair or major rebuild of a cavity section, you can trust our team to deliver the best quality

Grinding Down Welds: How To and Should You?

While grinding your welds, you end up removing some of the thickness from the weld and the base metal. Grinding welds does inherently does lead to a reduction in the strength of the weld, as you are removing some amount of material from the weld itself. The degree of weakening depends on the amount of material that is removed.

Cylindrical Grinding CNC Machining HTS Coatings

MachiningGrinding. In addition to thermal spray, HTS Coatings is a full-service precision machine shop. We offer both machining and grinding and can perform precision lathe machining, including inner diameter (I.D.) operations. Machining and grinding services can also be used during the thermal spray repair and overhaul process.

What is Welding? Definition, Processes and

Welding is a fabrication process whereby two or more parts are fused together by means of heat, pressure or both forming a join as the parts cool. Welding is usually used on metals and thermo but can also be

West Falls Machine, Co., Inc. shaft manufacturing, shaft

Grinding Services. If your product requires complex, multitask grinding and finishing operations, you’re contacting the right company. Large OD/ID and Surface Grinding Services. Outside diameter OD grinding up to 192″ long, shorter lengths up to 27″ in dia. Inside Diameter ID grinding up to 18″ dia. x 15″ long.

Welding Curtains Grinding Curtains Shaver Industries

Benefits. Our curtains are specially designed to protect from arc welding, grinding, and resistance from flying sparks. We ensure that visibility is available on both sides of the curtain. Welding and grinding curtains are a quick way to divide workspaces and also improves efficiency by defining work areas. The curtains can be moved quickly

Grinding on a D1.1 weld American Welding Society

2012年3月16日 There is no prohibition against the use of a grinder when making a production weld in D1.1. Again, a word of caution with regards to rejecting a production welds because the welder used a grinder to remove excess reinforcement, etc. Welder qualification is a separate activity from production welding.

Rail Grinding Types And Practices AGICO Rail

2020年10月30日 Rail grinding is one effective technique of railroad track repair and maintenance. By using rail grinders, rail defect material is removed and the rail profile is restored. Thus the service life of railroad track is extended. Rail defects. When talking about rail grinding, the rail defects are needed to be introduced first.

Weld Grinding Flexmill

Flexmill has developed wide range of grinding tools, process modules and complete fully automated solutions for weld grinding purposes. By using its extensive experience with process development, tool manufacturing and

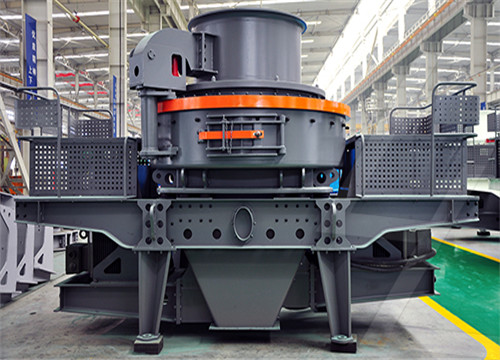

Pipeline Internal Girth Weld Grinding Robot Tyhoo Group

TYHOO ® -G WG Pipeline Internal Girth Weld Grinding Robot is a series of robots developed for the internal girth weld inspection and grinding of carbon steel, stainless steel and corrosion resistant alloy pipelines; it mainly serves in chemical, petroleum, natural gas, mining, nuclear power, aerospace, power and other industries. It is used for internal

Can fabricators really automate grinding?

2019年10月21日 Like in welding automation, grinding automation can approach a fixtured workpiece, but it also can be brought to a workpiece, especially when the workpiece is too large or unwieldy to maneuver easily. For instance, certain tank grinding applications today use an overhead gantry-mounted belt-grinding system that traverses across a workpiece

The importance of welding quality in ship construction TWI

1 Introduction. Welding is one of the most critical operations within ship construction. When welds fail, often the whole structure fails. [Apps et al. 2002] Over the past sixty years of developments in welding technology, the current expectation of weld

Everything You Need Know About Welding

2022年8月12日 Welding galvanized steel creates spatter and toxic fumes/smoke. Step 3– Arrange the workpieces to be welded and tack weld. Grind off the zinc layer from the welding location (1 to 4 inches on either

磨削加工中grinding, lapping, polishing 有什么区别?_百度知道

2007年1月24日 磨削加工中grinding, lapping, polishing 有什么区别?. 磨削加工中,grinding, lapping, polishing的字面上的翻译都是“研磨”,但实际上他们好像的精密磨削加工的三个不同的步骤?. 具体是怎么区别的呢?. 分享. 举报. 2个回答. #热议# 哪些癌症可能会遗传给下一代?. 海曼

Grinding on a D1.1 weld American Welding Society

2012年3月16日 There is no prohibition against the use of a grinder when making a production weld in D1.1. Again, a word of caution with regards to rejecting a production welds because the welder used a grinder to remove excess reinforcement, etc. Welder qualification is a separate activity from production welding.

Welding Curtains Grinding Curtains Shaver Industries

Benefits. Our curtains are specially designed to protect from arc welding, grinding, and resistance from flying sparks. We ensure that visibility is available on both sides of the curtain. Welding and grinding curtains are a quick way to divide workspaces and also improves efficiency by defining work areas. The curtains can be moved quickly