kraft cone crushers lubrication

Five steps to optimize crusher’s lubrication system Metso Outotec

预计阅读时间:4 分钟

Proper crusher lubrication Tip of the Week Lube Talk Mobil

2018年6月29日Oils: As a general rule, operators should use extreme pressure fortified gear lubricants with a minimum viscosity of 22 cSt at the bearing operating temperature.

Cone crusher maintenance critical to optimum output

2013年4月4日If your crusher is equipped with an external-mounted oil pump, the following must be carried out: • Lubricate the oil pump

Oil Lubrication And Filtration System For Cone crusher I

2020年6月11日8.7K views 2 years ago Lubrication oil circuit pushes oil through the crusher bearings. During the operation of the stone crushing, heavy dust produces and

Industrial Solutions Kubria cone crushers ThyssenKrupp

Kubria® cone crusher (1,100 mm cone diameter) in a quartz porphyry works Feed grain size 5 32/44 mm Product size 0 22 mm Throughput approx. 150 t/h Kubria® cone

Grease Lubricating System Used in Different Types of Stone Crusher

2021年10月23日In addition, it is highly recommended that crusher bearings be frequently re-lubricated to ensure proper lubrication or use high viscosity oil-based grease to

Crusher Lubricant™ ISO 220 Products D-A Lubricant

D-A Crusher Lubricant™ provides excellent performance in gyratory, cone and jaw crushers. It is also well suited for use in screen gearboxes and bearings requiring EP gear oil lubrication. D-A Crusher Lubricant™ is

Crusher Lubrication System OperationMaintenance

2015年7月18日Crusher Lubrication System OperationMaintenance For easy of OperationMaintenance, all Rock Crusher Lubrication System include their own monitoring devices, SIGHT GLASSES or VIEW

Kraft Cone Crusher Lubrication Kolorowakraina.waw.pl

[randpic]Mining Cone Crusher Lubrication, Cone CrusherKraft Cone Crushers Lubrication Kraft cone crushers lubrication we are a largescale manufacturer

5 tips for energy efficient and productive cone crushing

2020年4月15日Cone crusher lubrication pump maintenance If the crusher lube oil pump is not properly maintained and the flow rate decreases due to internal pump wear, circulating lube oil temperature will

Cone crusher maintenance critical to optimum

2013年4月4日USE THE CORRECT OIL. The type and condition of your lubrication oil is critical to successful operation of your cone crusher. Crushing with worn out oil or oil of the wrong specification can

Oil Lubrication And Filtration System For Cone crusher I YouTube

2020年6月11日8.7K views 2 years ago Lubrication oil circuit pushes oil through the crusher bearings. During the operation of the stone crushing, heavy dust produces and enters in to the

Mining tip revisited: Proper crusher lubrication Mobil

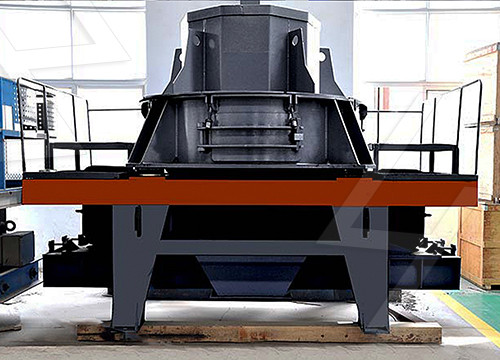

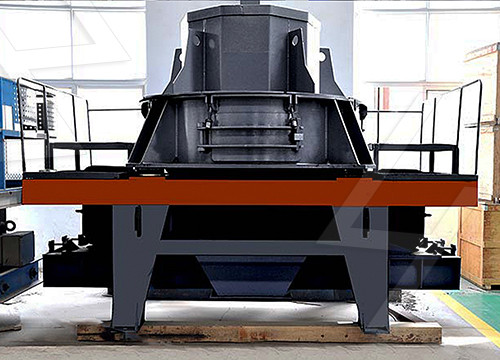

2020年1月17日Cone “gyratory” crushers: In a cone crusher, the main shaft is housed in a frame attached to a mantle. A pinion shaft assembly drives a bevel gear that rotates the cone. As material presses against the bowl, it is crushed into smaller pieces. Cone crushers have two radial and two axial bearings. The radial bearings are cylindrical roller

5 tips for energy efficient and productive cone

2020年4月15日Cone crusher lubrication pump maintenance; If the crusher lube oil pump is not properly maintained and the flow rate decreases due to internal pump wear, circulating lube oil temperature will

Industrial Solutions Kubria cone crushers ThyssenKrupp

Kubria® cone crusher (1,100 mm cone diameter) in a quartz porphyry works Feed grain size 5 32/44 mm Product size 0 22 mm Throughput approx. 150 t/h Kubria® cone crusher (2,100 mm cone diameter) for crushing granite Feed grain size 75 350 mm Product size 0 75 mm Throughput approx. 800 t/h Two Kubria® cone crushers (750

Crusher Lubricant™ ISO 220 Products D-A

D-A Crusher Lubricant™ provides excellent performance in gyratory, cone and jaw crushers. It is also well suited for use in screen gearboxes and bearings requiring EP gear oil lubrication. D-A Crusher Lubricant™ is

Crusher Lubrication System OperationMaintenance

2015年7月18日For easy of OperationMaintenance, all Rock Crusher Lubrication System include their own monitoring devices, SIGHT GLASSES or VIEW PORTS in the reservoir for oil level, FLOW METERS

Cone Crusher Explained saVRee

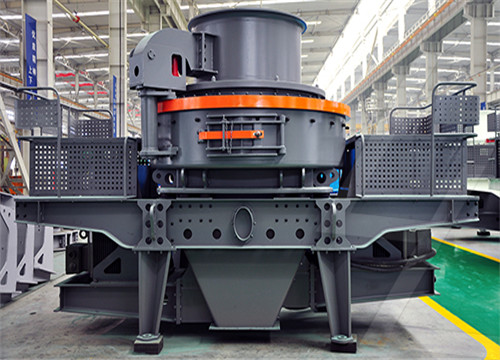

Cone Crusher Mantle Travel Path Crushed feed falls to the bottom shell assembly and is discharged to the product conveying system for further processing. The lower casing also houses a forced lubrication and

Understanding the Different Types of Crushers

Variable flow controlled by level sensors will ensure consistent feeding and maintain a full crushing chamber. Low oil temperature should prevent operation of the unit. High oil temperature should stop the crusher feed

Global Mining Review Lubricants for Compression Crushers Jet

2021年8月5日The three most common compression crushers are jaw, gyratory, and cone crushers. Cone and gyratory crushers are similar in operation and lubrication requirements. Before discussing the primary compression crusher lubrication points, it is suggested that all electric motors bearings be correctly lubricated with a suitable grease.

SANDVIK CS840i CONNECTED CONE CRUSHER

CONE CRUSHER CS840i is a high capacity cone crusher for secondary stage crushing. With up to 50% higher capacity, 25% increased reduction ratio and a reduced recirculation by up to 50%, with the same amount of high-value end product compared to similar crushers in its class, it is a true super producer. The wide range when it comes to

Kraft Cone Crusher Lubrication Kolorowakraina.waw.pl

[randpic]Mining Cone Crusher Lubrication, Cone CrusherKraft Cone Crushers Lubrication Kraft cone crushers lubrication we are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equi. 0086-21- [email protected] Inicio; Sobre nosotros; Productos;

How often do I change my cone crusher lubrication oil?

2019年10月23日The customer’s voice coupled with our promise “The Extra Mile Isn’t Extra. It’s Included.” has been a driving force in our business for over 110 years. In 20...

Cone crusher maintenance critical to optimum

2013年4月4日USE THE CORRECT OIL. The type and condition of your lubrication oil is critical to successful operation of your cone crusher. Crushing with worn out oil or oil of the wrong specification can

Mining tip revisited: Proper crusher lubrication Mobil

2020年1月17日Cone “gyratory” crushers: In a cone crusher, the main shaft is housed in a frame attached to a mantle. A pinion shaft assembly drives a bevel gear that rotates the cone. As material presses against the bowl, it is crushed into smaller pieces. Cone crushers have two radial and two axial bearings. The radial bearings are cylindrical roller

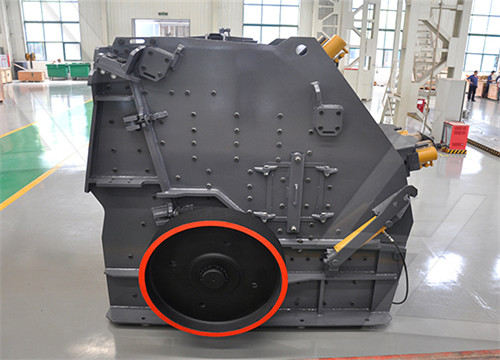

Industrial Solutions Jaw crushers ThyssenKrupp

ment of the crushing gap • Crushers can be used as stationary crushers or they can be integrated into wheel-mounted or track-mounted mobile crushing plants • Central lubrication system ensures a reliable lubricant supply From top: Single-toggle jaw crusher and double-toggle jaw crusher Over a hundred years of experience in manufacturing jaw

Crusher Lubricant™ ISO 68 Products D-A Lubricant Company

Crusher Lubricant™ ISO 68. D-A Crusher Lubricant™ provides excellent performance in gyratory, cone and jaw crushers. It is also well suited for use in screen gearboxes and bearings requiring EP gear oil lubrication. D-A Crusher Lubricant™ is specially formulated to be compatible with bronze and brass bushings and bearings.

Crusher Lubrication System OperationMaintenance

2015年7月18日For easy of OperationMaintenance, all Rock Crusher Lubrication System include their own monitoring devices, SIGHT GLASSES or VIEW PORTS in the reservoir for oil level, FLOW METERS

Understanding the Different Types of Crushers

Variable flow controlled by level sensors will ensure consistent feeding and maintain a full crushing chamber. Low oil temperature should prevent operation of the unit. High oil temperature should stop the crusher feed

cone crusher lubrication system YouTube

2016年10月21日About Press Copyright Contact us Creators Advertise Developers Terms Privacy PolicySafety How YouTube works Test new features Press Copyright Contact us Creators

sbm/sbm kraft cone crushers lubrication.md at main

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Kraft Cone Crusher Lubrication Kolorowakraina.waw.pl

[randpic]Mining Cone Crusher Lubrication, Cone CrusherKraft Cone Crushers Lubrication Kraft cone crushers lubrication we are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equi. 0086-21- [email protected] Inicio; Sobre nosotros; Productos;

SANDVIK CS840i CONNECTED CONE CRUSHER

CONE CRUSHER CS840i is a high capacity cone crusher for secondary stage crushing. With up to 50% higher capacity, 25% increased reduction ratio and a reduced recirculation by up to 50%, with the same amount of high-value end product compared to similar crushers in its class, it is a true super producer. The wide range when it comes to

Regular crusher maintenance integral to reliability, performance

2017年8月8日Checking the strainer basket on a cone crusher ensuring that there are no signs of excessive wear or damage to internal components; Greasing bearings if required to ensure proper lubrication and cooling of those bearings. If operators do not follow a maintenance plan and carry out daily inspections, it can have detrimental effects on the

® HP Series™ cone crushers Metso Outotec

Cone crushers Features ® HP Series™ cone crushers are reliable rock crushing machines for all demanding quarrying, mining, and tunneling applications. Over the years they have become the most popular modern cone crushers in the world with over 10,000 machines sold globally. Contact our sales experts Optimized performance

Minerals Processing Systems J SERIES

Trouble-free operation with controlled lubrication Automatic lubrication with external air-cooled unit. Oil temperature to the crusher bearings and gearing is controlled within fixed limits. Monitor on the oil filter. Crusher automatically stops if the oil flow is too low. Automatic motorised spider bearing grease pump.